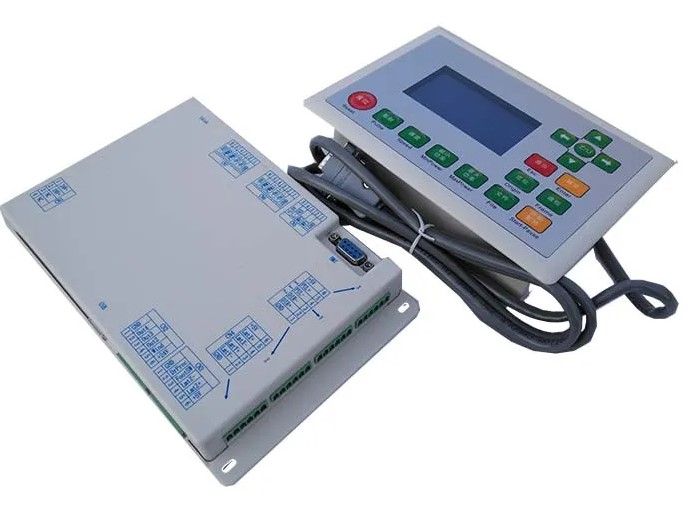

Upgrade your laser engraving processes with the LASERPWR Co2 Laser Engraving Controller System, where precision meets efficiency. Designed to meet the demands of modern engraving tasks, this advanced controller system offers unparalleled accuracy, speed, and reliability, ensuring your engraving projects are executed flawlessly every time.

Key Features:

High Precision Control: The LASERPWR Co2 Laser Engraving Controller System provides precise control over the laser beam, allowing for intricate and detailed engraving on a wide range of materials.

Swift and Accurate Processing: Experience rapid processing speeds without compromising on the quality of engraving. Achieve intricate designs and smooth finishes in record time.

User-Friendly Interface: The intuitive interface makes it easy for both beginners and experienced users to operate the system. Effortlessly create, edit, and execute engraving tasks with a user-friendly control panel.

Compatibility: This controller system is compatible with various Co2 laser engraving machines, offering seamless integration and enhancing the performance of your existing equipment.

Real-Time Monitoring: Monitor the engraving process in real-time, allowing you to make adjustments on the fly and ensure the perfect outcome for each project.

Benefits:

Enhanced Productivity: With rapid processing speeds and precise control, the LASERPWR Co2 Laser Engraving Controller System significantly boosts your productivity, enabling you to take on more projects efficiently.

Versatile Engraving: From intricate designs to large-scale patterns, this controller system handles a wide array of engraving tasks on materials such as wood, acrylic, glass, and more.

Cost-Effective: Reduce material wastage and enhance efficiency, leading to significant cost savings in the long run. Minimize errors and rework, optimizing your resources effectively.

Reliability: Built with durability in mind, this controller system ensures consistent and reliable performance, minimizing downtimes and maximizing your operational efficiency.

Why Choose LASERPWR Co2 Laser Engraving Controller System:

Cutting-Edge Technology: Stay ahead in the engraving industry with state-of-the-art technology that ensures you deliver high-quality results to your clients.

Technical Support: Benefit from our dedicated technical support team, ready to assist you with any queries or concerns, ensuring you have a seamless experience with our controller system.

Customizable Solutions: Tailor the LASERPWR Co2 Laser Engraving Controller System to your specific needs, allowing you to adapt the settings and configurations based on your unique engraving requirements.

Upgrade your engraving capabilities with confidence. Choose the LASERPWR Co2 Laser Engraving Controller System for unmatched precision, speed, and efficiency in your engraving projects. Elevate your craftsmanship and deliver superior results every time. Experience the power of precision and efficiency combined.

Installation and Integration:

Installing the LASERPWR Co2 Laser Engraving Controller System is a streamlined process, ensuring minimal disruption to your operations. Our detailed installation guides provide step-by-step instructions, making it easy for your technicians to set up the system. Our support team is always available for assistance, guaranteeing a smooth integration with your existing Co2 laser engraving machine. Once integrated, the system seamlessly synchronizes with your equipment, allowing you to harness its full potential without any complications.

Optimized Workflow:

With the LASERPWR Co2 Laser Engraving Controller System at your helm, experience a transformed workflow. The system’s intelligent algorithms optimize the engraving path, minimizing processing time and maximizing efficiency. Whether you’re working on intricate designs or large-scale projects, the optimized workflow ensures consistent and high-quality results, enhancing your reputation and customer satisfaction.

Real-Time Monitoring and Control:

Stay in command of your engraving tasks with real-time monitoring and control features. The system provides live feedback on the engraving process, allowing you to make adjustments instantly. Monitor progress, adjust settings, and preview the engraving outcome in real time, ensuring precision and accuracy in every project. This real-time control not only enhances the quality of your work but also saves valuable time, enabling you to meet tight deadlines with confidence.

Comprehensive Technical Support:

At LASERPWR, we understand that your success hinges on reliable technology and excellent support. Our comprehensive technical support is available 24/7 to address any queries, troubleshoot issues, and provide expert guidance. With our dedicated support team by your side, you can focus on your craft, knowing that you have a reliable partner to assist you whenever needed.

Unleash Your Creativity:

The LASERPWR Co2 Laser Engraving Controller System empowers you to push the boundaries of your creativity. With its precision, speed, and versatility, you can bring intricate designs to life, add intricate details to products, and explore new artistic horizons. Whether you’re in the business of personalized gifts, industrial engraving, or artistic creations, this controller system amplifies your capabilities, allowing your creativity to shine.

Invest in Excellence:

Elevate your engraving endeavors with the LASERPWR Co2 Laser Engraving Controller System. Invest in cutting-edge technology that not only meets but exceeds industry standards. Take the next step toward precision, efficiency, and unmatched quality in your engraving projects. Experience the seamless integration, unparalleled support, and transformative impact on your workflow. Upgrade to LASERPWR Co2 Laser Engraving Controller System and redefine what’s possible in the world of laser engraving. Your journey to precision and efficiency begins here.